An Easy Guide to Build a Carport with Steel Pipe

- Kunal Singh

Carports are best to provide shelter to your cars, RVs, tractors, and boats from sun heat and rain. Therefore, adding a metal carport to your home can be an aesthetical life-altering decision. For an alternate affordable option, the internet is flooded with many ideas and youtube videos on how to build a carport. If building a carport with used steel drill pipes has got your attention, then you need to read this entire blog. You will not only find different steel pipe options available in the market but will be empowered with the correct information on how to build a carport and carport installation.

Metal Carport by Steel and Stud is a great and effective alternative to a garage. They are a reasonably cheap option to enhance your facade. Steel and Stud operate in most parts of the United States, offering installation services by trained experts for the perfect structure.

If your location permits, the options for metal building or structural installations. In that case, our professionals can easily install these freestanding structures. Steel and Studs also offer the customization option, painting the steel frames and choosing roofing material accordingly to make it appear as a part of your original home design.

Table of Contents

Options for Steel Tubing:

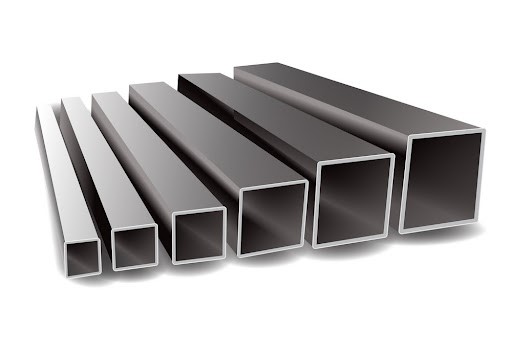

Whenever we think of a steel pipe or steel tubing, we either relate it to plumbing or from the industries that use the pipes for transportation. But, apart from these two common uses, steel pipes and tubing offer huge options for strong and affordable freestanding structures, depending on your settings. Five different types of steel pipe and tubing that can enhance the quality and overall look of your carport-designed layouts are:

1. Drill Steel Pipe:

Drill Steel pipes are primarily used in the Texas region for drilling rigs. The drill steel pipes can then be used to give an enhanced look to a fence, an effective alternative to the good-looking and sturdy enclosure. Drill steel pipe is an affordable option for constructing pole barns and other metal sheds used for farm equipment storage.

2. Steel Pipe:

Steel Pipes are a lightweight, affordable option for carport structures and the best option for framing posts. But the thickness of hollow steel pipes has some limitations that restrict their infinite uses. Steel pipes may hold strong against the wind, load, and other major requirements, but a few may not be able to fill up with a high-pressure gas or fluid. Seamless steel pipe may look like the best option for building a sturdy garage and metal carport structures, but fine welded steel tubing as per the design are also safe to use and versatile.

3. Square Tubing:

Square tubing is another incredible option for steel pipes. Square shaped is attractive and is commonly used due to its structural edge strength and adaptability for columns, gates, and attractive dividers in framing carports. It can preferably be used for larger metal building projects, structural applications, trailer frames, and even for the automobile manufacturing industry.

4. Pole Barn:

Pole Barn is a bunch of steel pipes or poles stuck with a hole in the ground, extending support to the roof. The strength of these bunch of poles is usually used to build reliable, sturdy, and affordable building structures. Moreover, pole barns are available in all the possible shapes and sizes, where some of them don’t even look like steel pipes, offering easy customization options to fit the designs of existing layouts.

5. Round Steel Pipe:

Round steel pipes bear more strength than any other steel tubing framework for a carport. Because of its flexibility and strength, round steel pipes are increasingly used for metal buildings and other portable or temporary structural options, including carports, garages, and other multi-storage options.

Steel and Studs offers a variety of galvanized and red iron oxide steel pipe options, including round and rectangular steel tubing, which is anti-corrosion and rust-free. Steel pipe can add strength and security to your commercial or residential properties even after being lightweight and cheap material for the framework.

If you live in a place where metal structures can be installed, then Steel and Stud can help you find custom solutions for carports to protect your cars and other transportation modes from external damage.

How To Build a Carport Out of Steel Pipe?

1. Pre-Installation Steps:

Before you plan to set up your steel carport and gather all the tools, bolts, and other equipment, it’s important to check and cover a few essential things first. It will further ensure safety and legal procedures down the track.

- Plans and Permits in order:

Firstly, you must go through the right local authorities to obtain the desired permits and codes on the ground. It will ensure that external or structural constructions are allowed in your location and help meet environmental, safety, and heritage requirements.

- Locate your Amenities:

The next step would be locating and measuring where all your electricity and water services tracks are laid down. It will help avoid any damage during the construction and post-hole digging process.

2. String Lines for Metal Carport Post:

When building your carport or assembling the pipes, it is important to get the correct measurements and ensure that the strings attached with bolts are in the desired shape and size, especially for the front two posts.

- Hurdle and String Line Setup:

After measuring the approved project, mark your four or six posts at the corners of the site. Mark the measurement on the hurdle and run string lines parallel to them. Continue to youtube DIY videos to measure the effectiveness and your working procedure.

- Metal Carport Height and Shape:

Measure the correct height of the carport according to the approved project and mark it against the fence. Also, make sure that the carport is parallel to the paving. Measure the distance between strings to get desired measurement and location for the roof.

3. Post-Hole Supports for the Carport:

Supports are among the first installation while building the carport. Follow the string lines to get the perfect level and desired measurements, and cut a hole in the exact location to support the beams.

- Dig Holes:

On the marked string line measurements, mark the holes for four posts and dig them. But, before starting the post- digging process, make sure to check the water and gas pipes to prevent leakage.

- Place the Supports:

Post the steel pipe supports in the holes and cover them with concrete on the ground. Use the string lines to ensure the site level and let the solution set for a few hours.

4. Beams For Support:

- Mark the Beam Height and Cut out in the Post:

Measure the desired beam height for the carport and trim the steel pipes accordingly. After marking the height, cut the post to help support the beam.

- Place the Beams:

After cutting out the holes in posts to get beam support, place the beams and weld them at the gable edges to prepare the roof structure.

5. Truss Welding:

After setting up beams and posts, the next step is to weld the truss. Place it on the beams according to the measurements and continue with the welding process to get the roof.

6. Red Oxide Primer:

Depending on the product situation, you can apply the red oxide primer coat on the post and beams to prevent the steel pipes from rusting or other external damaging factors. You can also purchase the oxidized red beams from us.

7. Assemble the L beams:

After applying the red oxide coat, assemble the cut an L beam on the edges to get the finished look of the carport frame.

8. Install the Ridge Cap and Gable trim:

The last and final step would be to install the gable trim. It is to finish off the edge of the roof and will be installed on the two high sides. Lastly, place and weld the ridge cap, depending on your settings, to get a shield and finish off the task of building a covered carport.

What are the Benefits of Using Steel tubes instead of Solid Section Steel?

Tubular Steel sections are strong against longitudinal stress, which is why steel tubes are used as scaffolding. Steel tubing and pipes’ resistance to compression and bending forces is better than that of flat sheets.

On the other hand, the solid tubes are comparatively heavier than steel tubes, increasing the load on the surface and the cost of project construction. Steel pipes are also less suspectable to signs of corrosion, which is why they are economical in the long run.

Advantages of Steel Tube:

- Steel tubes are hollow, decreasing their weight and load on the metal carport surface.

- Steel tubes have greater strength and are an ideal option for the post.

- These tubes can easily be found in multiple sizes, unlike solid sections, which are manufactured only in some standard sizes.

- Steel tubes have a consistent thickness, cross-sectional shape, and diameter throughout their length.

Iron Framed vs. Tube Frames- Which one to Opt?

Tube Frames:

As the name defines, Galvanized steel tube frames are hollow metal tubes that can be found in both round and rectangular shapes, ideal for posts. Tube frames will look like pipes and can be ordered with different thicknesses and diameters range. These frames are therefore affordable and easy to use.

But at the same time, the hollow tubes offer less structural strength and resistance, increasing their damage chances easily from harsh weather. To increase the resilience of tube-framed structural buildings, posts are placed every five to eight feet, increasing the material quantity and cost.

Pros of Tube Frames:

- Ideal for DIY projects,

- Available at low prices,

- Lightweight.

Cons of tube Frames:

- Increase the overall material quantity,

- Poles are placed every five to eight feet,

- Structurally Weaker

Iron Frames:

Iron-framed buildings, on the other hand, are made from rigid metals that have the power to withstand all the damaging external factors. These are made from red iron and are known as L-beams due to their design.

But due to their heavy weight, these iron frames are not easy to work and install. These heavy metals are installed with heavy machinery to ensure correct placement, increasing the overall installation costs.

Pros of Iron Frames:

- Versatile

- Durable, strong, and reliable.

Cons of Iron Frames:

- Requires a strong foundation,

- Not for DIY projects,

- Expensive option.

Frequently Asked Questions:

- Are rectangular steel tubes stronger than round for four posts?

Compared to rectangular tubes, cylindrical tubes have more strength as they eliminate the weak points of four corners or posts, increasing the overall strength and resistance to torsional twisting underweight. - How much weight or roofing material can rectangular tubes withstand?

The tensile strength of the rectangular tube can be upto 100,000 pounds per sq. inch, depending on the alloy, size, and material. - I want to install 2 Car space carport in my backyard. Which is stronger, I-beam or square tubing for such a structure?

Due to greater section modulus, l-beams are stronger. The resistance further also depends on the location for the placement of l-beams.

Conclusion:

Iron steel pipes come in various ranges and are sometimes not too easy to operate. Videos over the internet may promise hassle-free installation, but the DIY process is time-consuming, tiring, and requires expert attention. Steel and Studs are the most reliable carport provider in the United States, extending the professional installation support. Check our website to understand how our services work for the effortless final products. Customers increased engagement and site statistics prove that we are doing the right thing regarding reliable metal building kits.

If your town or location finally approves the construction of metal buildings, then Steel and Studs will offer wide customization options for carports, which will appear as a part of your designed house only.

Indoor Riding Arenas: Types, Features, Benefits, and Cost

Different Types of Metal Roofing for Commercial and Residential Buildings

What Is A Purlin? Types, Sizes, Designs, Accessories & Cost