Metal Building Trims: Types, Installation, Benefits

- Kunal Singh

A house needs protection and aesthetics. By using metal building trims, we will easily be separated from ordinary-looking houses. These are also great for living in a fully steel-built abode and 40% more rigid than wooden houses.

They are decorative and offer protection from the weather too. These are available in different types, each one to match our building structure. We can also choose trims for any customization, depending on our expertise.

In this post, we’ll look at several elements and sorts of metal trims, as well as how Steel and Stud can provide the ideal metal trimmings for your next big project.

Table of Contents

Metal Building Trims

The trims are metal sheets in parts that are folded. They work to keep the roof waterproof.

The large lengths maintain consistency. Their application is very simple for makeovers of the home or shed.

Generally, water damages different parts of the metal roofing during rain. But metal trims will seal the joints and keep off moisture. They will allow roof panels to connect from edge to edge in the roof and give a polished look.

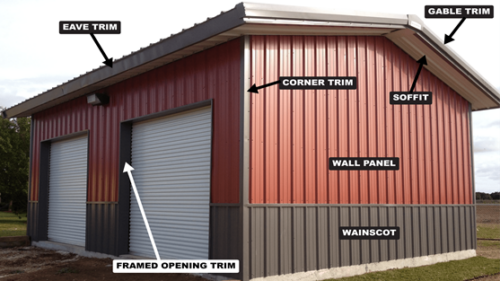

Standard Features & Items of Metal Building Trims

It comes with a steel coil of around 4m long and 0.6mm thick, with overlaps of 50-100mm thickness. It also includes steel sheets of 20 inches-26-gauge material.

Some of the items include but are not limited to:

- A box and sculpted gutter

- Box rake and sculptured trim

- Peak and corner boxes

- Different downspouts

- Different eave trims

- Corner trims in different panels

Other trims include a jamb, head, sill, cap, drip, starter, and transition, and also a ridge drip cap, soffit, and valley flashing.

You’ll also find either galvanized or colored metal trims.

Types of Metal Building Trims

Here we discuss different metal building trim types:

Roof ridge cap

This one offers an intersection between two roofs at the ridge. So, the roof is free from leakage and rain.

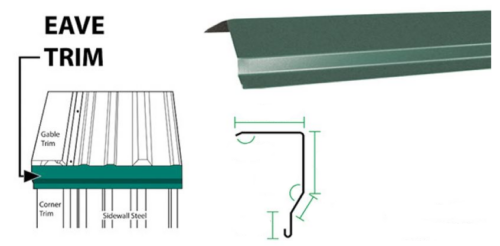

Metal Building Eave Trim

This custom trim stays at the roof’s end and also at the top of the panel. It offers an aesthetic look. It also prevents moisture to enter the wall and panels.

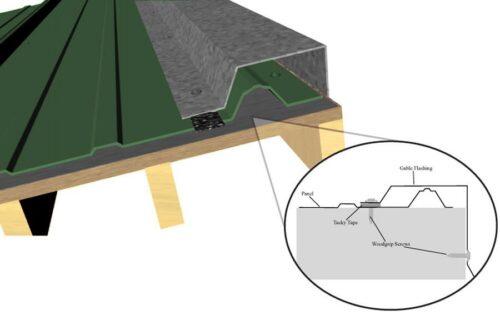

Gable trim

Gable trim offers a panel that remains water-resistant. It is placed between the panels of the wall. For this, it can block steel plates and prevent water from coming inside.

Gutter

We can place this on the edge to lead the rainwater to a downspout. So, instead of collecting on the steel roofing, the water will flow towards the ground.

Wall Corner trim

As the name says, this trim remains at the wall’s outside corners. So, mostly it works for the decorative part but also removes water so that it doesn’t enter the building.

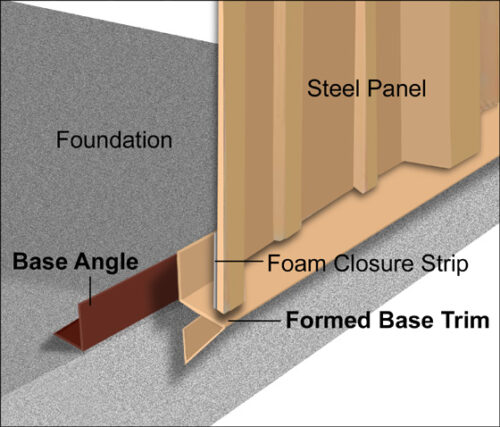

Metal Building Base Trim

The intersection of the panel and wall is made of a base. This trim will cover this base and prevent any water from entering the building. It even covers the metal building windows and the doors.

Metal Building Rake Trim

This is an angled trim to fit the roof pitch. So, the trim can cover the seam of the roof. Both the roof panels and end wall panels are covered with no overhanging roof line.

J-Channel Trim

The J-channel trim offers a very sleek appearance. These are quite efficient and easy to clean. Having J-channel trims makes windows and siding installation extremely easy and seamless.

Jamb Trim

If you want to add extra protection across your doors and windows, you must depend on jamb trims. Featuring a polished appearance, these would help remove extra water and debris.

Valley Trim

The valley trim protects the intersecting panels of the two slopes. Since it is shaped in a valley-like format, it ensures the water easily runs off without causing any leaks or external damage.

Z-Trim

If you’re looking forward to combining functionality and aesthetics in metal trims, nothing can work better than Z trims. These add depth, thereby creating the desired visual appeal.

Hemmed Eave Trim

This type of trim is mostly used on the edge of the roof. Since the edges are secured, there is no risk of damage due to water infiltration.

Fascia

Fascia helps in covering the roofline. It provides a watertight seal across the roof, thereby protecting the aesthetic appeal of the roof.

Fitted Ridge Trim

As the name suggests, the fitted ridge trim protects the roof’s ridges. The roof’s highest point receives a watertight seal, thereby enhancing a finished appearance.

Sidewall trim

Rather than the roofs, the side wall trims often protect the sides of the walls. Contrary to the other methods, the side wall trims are installed vertically. As a result, the frames are protected against any potential damage.

Endwall

Endwalls are installed across the end of the building. With a finished edge, there is no risk of water intrusion. As a result, there is no potential damage.

Metal Building Corner Trim

With the help of corner trim, you can easily protect the extreme corners of the exteriors. With increased strength and durability, the corner trims offer a clean and sleek appearance.

Drip Edge

One of the major functions of drip edge is to prevent the water from seeping in. Since it is installed across the roof edges, the water will be redirected to the fascia, preventing damage to the entire structure.

Material Used in metal building Trims

Functionality, aesthetics, and durability are the three primary criteria for selecting materials for metal building trims. Take a look below to understand what materials to choose from:

Steel

The strength and affordability make steel an absolute favorite for metal building trims. The effective structural integrity of steel makes it an efficient choice, as it can effortlessly handle harsh weather conditions. And it’s not only functional but also aesthetic, as steel provides a sleek and modern look.

Aluminum

Whether you want to use aluminum for exteriors or interiors, these suit the purpose of resisting corrosion. Being lightweight, aluminum is extremely versatile and can be molded into designs of personal preference. Aluminum is one of the prime choices because of low maintenance and is fading and dust resistant.

Galvanized Steel

Galvanized steel, with its additional zinc layer, helps offer protection against corrosion. Owing to its durability, the galvanized steel trims can easily withstand moisture. Therefore, if you’re in a high-humidity area, you must opt for the galvanized steel trims.

Stainless Steel

Whether it’s heavy damage, corrosion, or rust, stainless steel trims are here to fight it all. With a modern and polished appearance, stainless steel trims enhance aesthetics. As far as functionality is considered, these can serve well across healthcare facilities and food processing plants.

Copper

With their distinct patina, the copper trims add character and charm to the buildings. If maintained properly, the copper trims can last for generations serving numerous benefits.

Zinc

You can never go wrong with zinc trims. These are highly suitable for areas with high humidity, especially coastal areas. You don’t have to worry about corrosion if you have zinc metal trims, for they can eventually help get rid of it all. Also, it’s lightweight and doesn’t require much maintenance, so you can use it without burning a hole in your pocket.

Effects of Metal Building Trims

We will have two effects on the roof. One is the prevention of water leakage, and the other is a decorative finish.

Whether trims offer an intersection or remain at the edge, corner, or angle, their purpose is to cover the opening. This will either block the rainwater or make them flow to a different route.

Besides, the color options, shape, and finish of each trim offer a beautiful structure.

Why is Opening Trim for Metal Buildings so Important?

Opening trim will allow us to give a polished look to the metal building. We can change the color and texture. Besides, they are used to cover the wall panels and roof edges from all sides. This will ensure that the trims can seal the areas properly.

Then the roof can remain waterproof by making the rain flow downwards outside the building.

Factors to Consider When Choosing Metal Building Trims

Selecting the metal building trims is not an easy find. So, how do you do it? Well, go through the points below to find the perfect choice:

- Climate and Weather Conditions: Before getting the metal building trims, you must assess the climate and Weather conditions. For example, areas with high humidity will require corrosion-resistant trims. Areas with strong winds and harsh weather conditions must have strong metal trims.

- Aesthetic Appeal: While choosing the metal building trims, you must focus on meeting cohesive design with visual appeal. You must know what architectural style you’re looking for so that it can complement the desired aesthetic for the metal building. Depending on this, you can choose from modern to rustic appearances.

- Maintenance and Durability: Every metal trim is different and will have different maintenance requirements. While some materials are high maintenance, others are low. You can choose the trims depending on what you’re the most comfortable with.

- Cost: Staying on a budget is extremely important when choosing metal trims. However, while choosing, you have to compare the cost and what value they add in the longer period. For example, some materials may have a higher installation cost, but in the longer term, they can serve more purpose proving to be cost-efficient.

- Compatibility with Other Building Materials: Your building wouldn’t only need trims and many other things. So, before making your choice, you must also consider its compatibility. The metal trim you choose easily blends across roofings, windows, or sidings for a better aesthetic appearance.

- Installation Process: The ease of installation is one major factor one shouldn’t overlook. Therefore, it is necessary to be familiar with the complexity of the installation process. While some materials may be easy to work with, others may need the expertise of professionals like “Steel and Stud”. It is advisable to check the complexity of installation for the material and the workforce required for it.

How Much Does Trim Cost?

The metal building trim prices depend on the type of trim we use and our roof system. Generally, the cost can range from $8 to $20 per linear foot. The Eave and gable trim cost around $2 to $3 per lineal ft and ridge caps cost from $2.50 to $4 per linear ft.

Installation Process of Metal Building Trims

Since metal building trims are slightly complicated to deal with, installing the same requires attention to detail. A detailed process and following the guidelines can help to ease the installation process:

1. Tools and Equipment Needed

Before starting the installation, you must have all the necessary tools ready. Some major tools and equipment you will need for metal building trim installation include shears, screws, safety gear, and more. If you don’t have the gears, you can get help from Steel and Stud professionals.

2. Safety Precautions

Safety should always be a priority during the installation process. While working on the installation process, it is advisable to use a flat surface. Irrespective of where you install the metal building trims, you must avoid doing so during harsh weather conditions.

3. Preparation

Preparation is the second thing to take care of for installation. Always make sure to compare in terms of preparation. Double-check the measurements and prepare accordingly for putting up the metal trims.

4. Installation Steps

Foundation preparation is one of the most important steps of installation. It is important to follow the manufacturer’s guidelines during the installation steps. At Steel and Stud, we will guide you from the first till the end step for installation.

5. Finishing Touches

After you’re done with the installation, you must add some finishing touches. During this, you must look out for potential gaps that may possess a threat to your property.

Why Trim Is Important To The Success of Your Metal Roof?

You need a damage-free roof, and trims are the answer to it. A successful installation will give you a roof that will last a long. It will not only protect from moisture but also other elements that can cause damage. As a bonus, you get a perfectly structured and textured rooftop.

Maintenance and Repair of Metal Building Trims

By regularly indulging in the maintenance and repair of metal building trims, you will be able to preserve the appearance and enhance longevity.

Regular Cleaning and Inspection

Regular cleaning and inspection contribute to removing the dirt and debris from the trims. It is advisable to use mild detergent and water mix to remove contamination. After the cleaning, you must inspect for corrosion or external damage to address the problems and make changes accordingly.

Repainting

The paint on the metal building trims may fade after some time. The only way to recover would be to re-do the entire thing. If there are loose paintings, you must remove them using a brush and then repaint the area. Repainting will help in holding the aesthetic appeal.

Repairing Damaged Trims

If any metal trims are damaged, you must take quick action and repair them. Not repairing the metal trims will only cause further damage, weakening the entire structure. You must address that concern with Steel and Stud if you find damaged trims. We will take it up and resolve it at the earliest.

Get Your Quote From Steel And Stud

Steel and Stud will offer the right compatibility for trims. You will get the fastest delivery, best service, and free-of-charge quotes. We consider customers’ convenience and the best price for our products and services. Please contact us today to get special offers.

FAQs Related to Metal Building Trims

Every metal building trim has a warranty period so that you can stay prepared to make the changes in time.

Many residential projects have used metal building trims considering convenience and affordability.

You must measure the area size to know the appropriate size of your metal building trims.

A major reason for metal building trims to become popular is their recycling capability.

The metal building trims do not burn a hole in your pocket, catering to affordability and efficiency.

Metal building trims have a good longevity of around a decade.

Under expert guidance, you can easily customize metal building trims. Steel and Stud are there to assist you every step of the way.

The drip edge is one of the major components of the metal roof.

Unfortunately, the installation is quite complex. You need to be patient and careful while working if you decide to install by yourself. Otherwise, slight mistakes can lead to failure which won’t prevent water leakage.

With the help of experts at Steel and Stud, you can indulge in installing the trims seamlessly.

Indoor Riding Arenas: Types, Features, Benefits, and Cost

Different Types of Metal Roofing for Commercial and Residential Buildings

What Is A Purlin? Types, Sizes, Designs, Accessories & Cost