Rafters vs. trusses – roof framing best for your metal building?

There has never been a better time to construct an auxiliary building such as a pole barn or carport. Steel structures are easier to build and stronger than ever.

Framing the roofs has been one of the hardest processes in building any metal or wooden buildings. But if you select the correct construction style for your required metal building, you will have years of faithful service.

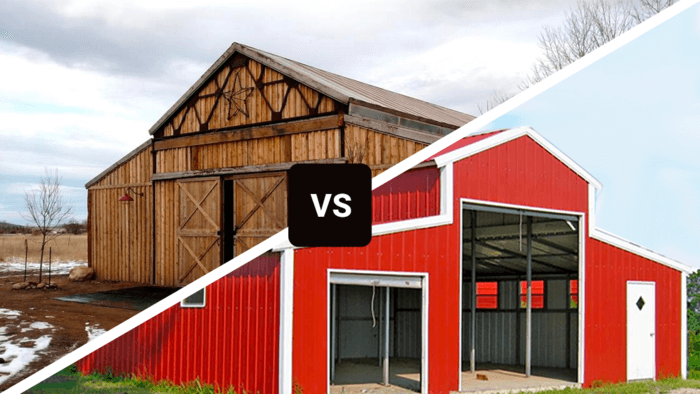

Both Rafters and Trusses are two common terms used for framing roofs. Though many contractors and builders use it interchangeably, Rafters and Trusses are different roof structures with unique advantages and disadvantages.

If you are planning a metal carport, shed, or living quarter, you need to know the difference between the two, their best applications, and a comparison of their prices and purpose.

To equip our readers with the right knowledge and understanding of metal building, Steel and Stud have complete resources of blogs and videos on our website. Here, we have clearly defined metal, rafters, and trusses for you in detail. Understanding their pros and cons will help you determine the best option for your metal building home.

What Types of Roof Framing are Available?

You will encounter two types of roof framing systems in residential construction projects.

Conventional rafter framing

Manufacturing roof trusses

However, first, let us briefly look at the differences between the two

While traditionally, roofs were constructed using rafters, also known as stick framing wood. Since metals such as steel have become a much more popular way of quickly and efficiently building, a strong and long-lasting roof truss system is preferred in the current time.

You may be asking yourself, “What is the difference between roof trusses and roof rafters?” so, with that question in mind, let’s look at each system’s key features.

Metal Rafters

Metal roof rafters are a modern take on one of the oldest roof construction methods in existence. Much like their lumber counterparts, metal rafter roofs are made from sloped beams which join in the middle to form a peak known as the roof ridge.

Equally spaced between the central ridge beam and the bottom of the rafters, support ceiling joists, sometimes known as purlins, can be used for additional strength. At the bottom end itself, metal rafters are mated to ceiling joists where the vertical structure meets the sloped frame.

Rafters are structures that support a roof.

When rafters are constructed to support a roof, the process is like creating “stick framing.”

The Rafter Roof support structure is basically a simple triangle.

There is more attic space in rafter framing

2 x 10s or 2 x12s are the most common dimension for installing rafters.

Roof rafters are onsite construction.

The roof rafters cost is less expensive

What are the Benefits of Metal Rafters?

Although traditional rafters generally see something of a decline in use, a metal roof rafter still offers some great benefits that make them worth considering for your residential construction project.

Steel roof rafters can speed up the build if your rafter construction project is more bespoke than off-the-shelf. Because they are much simpler in design than other types of roof framing, the lead time for components is much shorter. So, if you are short of time, keep metal rafter roof framing on your radar.

Largely because of the low physical volume taken up by the rafter beams, they are perfect for use in buildings with vaulted ceilings or cathedral-style ceilings, which is necessary due to taller or more unusually shaped items being stored.

Additionally, because of the low volume, they are the perfect choice if you’re looking to increase your building’s useable open space with a loft or attic. Also, attic insulation is easier with rafters.

Rafters are usually delivered to the job building site in individual pieces and require full assembly. While this may not seem a rafters pros in the face of things, consider this a big plus if your project is in a remote location or somewhere where delivery of large pre-constructed components could pose logistical challenges.

Metal roof trusses are prefabricated framing structures comprised of top and bottom beams, known in the industry as chords, and in between the chords is a triangular webbing. Whether you are looking for a flat roof or a sloped roof structure, metal trusses can be used for your roofing project. The web framing ensures distributed weight on outside walls.

Metal roof attic trusses have a triangular shape.

Trusses are prefabricated units and are known for structural integrity.

This web-like roof trusses offer additional support to exterior walls.

What are the Benefits of Metal Trusses?

Metal trusses are rapidly growing in popularity as a framing material for roofs, and it’s easy to see why. The roof trusses are built to extreme tolerances on high-tech equipment. The structural engineer designs on CAD software and fabricates with laser cutting and automated welding techniques. Because they arrive at the job site in a pre-constructed state, truss construction is much faster to install and, in most cases, easier.

Trusses come into their own when used in large, open structures. Because of their design, they are inherently stronger than other roof framing and roof sheathing construction materials.

This inbuilt strength and truss spans allow the metal buildings to be built at incredible lengths(more than 60ft), allowing you to create wide open spaces without needing additional load-bearing capabilities.

An added bonus of metal truss roof construction is the aesthetic appearance. Using scissor trusses can help in steep vaulted ceilings. Suppose you’re not planning to cover up the interior framing of your roof. In that case, the design of metal trusses lends a contemporary industrial look to a space, and many find it very attractive. Also you can save labor and material costs with metal trusses.

Let’s recap the pros and cons of each roof construction style:

Metal Trusses

Pros

Faster installation

Extremely accurate sizing

Allow for true open spaces

Cons

Difficult to deliver to remote locations

More expensive

Longer lead times

Metal Rafters

Pros

Allow for vaulted/cathedral ceilings

Allow for additional roof storage space

Relatively inexpensive

Cons

Construction is time-consuming

Skilled labor is required for construction

Choose Rafters For Flexible Construction site

We suggest Rafters only when:

Our customer wants a dramatic cathedral ceiling

They reside in remote rural areas where prefab trusses cannot be easily delivered

They want more open attic space

They hire us or have skilled labor to install the rafters.

Choose Trusses Roof for Extra Strength

We recommend truss to our clients who are looking for

Affordable roof framing

Onsite quick construction

Robust and sturdy roofs to sustain heavy loads of wind, snow, or rain.

Longevity of your Metal Roof Frame

When it comes to the longevity of your metal framed roof structure, there are distinct advantages over a wooden structure, namely immunity to insects. Any wooden roof deck is vulnerable to termite and woodworm infestations, which can seriously affect the structure’s lifespan. Metal roof frames are constructed from high-grade materials and are often galvanized for excellent corrosion resistance.

Another great feature of a metal roof structure is the fact that metal can be certified to be uniform and consistent in its molecular structure. When horizontal beams are forged in the same batch, they can be guaranteed to be of the same strength and weight. Wood, by its very nature, is completely unique in every cut plank. This can mean different weights and different strengths in different areas of the structure.

Conclusion

Of course, the use of metal in roof framing, no matter the type, has drastically improved the way we construct buildings today. Both types we discussed here, metal roof trusses and metal rafters, are great options for your next project and are ideally suited to their applications.

There are trade-offs when you select either method, but the unique factor here, is that some other elements offset those same trade-offs; for example, the time saved by the shorter lead time on rafter materials is made up with a simpler and faster build at the construction site with trusses.