Is it possible to build my own metal building?

Building and construction is a vastly growing industry globally attributed to technological advancements and the growth of the global economy. This advancement has generated new building materials, architectural designs, and policies. Among them is the fast-growing metal buildings idea. Metal buildings have been accepted widely in the building and construction industry, with the buildings being preferred since they have more advantages over buildings constructed from traditional materials; brick, stone, and timber.

DIY metal building kits are more resistant to harsh weather conditions like snow, sun, rain, and wind. Anchored firmly into the foundation – mostly concrete – the building is sturdier and offers assurance of protection. Your own metal building offers you added space in your compound to store your valuable items. The DIY steel building kits are resistant to corrosion – especially those made from red iron and are relatively cheaper.

The construction of a steel building is technical and may not be as easy as using traditional building materials. However, the complexity of the steel building depends on the function and how big the building is. This means that you can construct your own steel building. We will provide you with insights on your own metal building construction.

Table of Contents

Build Your Own Metal Building

With the mention of metal building, most people deem them as an extremely complex building they cannot build. However, coming up with your steel building is not an idea that cannot be achieved. In fact, if you contact Steel and Stud, construction becomes more manageable and achievable.

You can do it yourself, famously known as the DIY project method, or you can contact a construction company to do all the construction work for you, referred to as the Turnkey method. This Turnkey method introduces pre-fabricated metal buildings into your proposed space. Also, the DIY steel building kits can be assembled on the ground, with all the work being done by hired professionals.

Embracing the DIY method is preferred by quite a several people as they prefer to get their hands on the work themselves. However, an excellent DIY steel structure is achieved by individuals who;

- Have some basic knowledge or construction experience

- Their construction is not massive and, thus, is small to medium-sized

- Know family or friends who are dependable and can help in erecting the building

- Can follow the safety instructions inscribed in the manual carefully

- Can study the building manual carefully and thoroughly before beginning the construction

Things to Consider While Building Your Own Metal Building

Budgeting

Building your metal building is no small task, for you will need to plan out many things on your own. Well, budgeting is one of the main things to consider while building your metal building.

While preparing the budget, you must take advantage of even the most minor details.

You will need to look for factors like the cost of materials, permits, labor, etc. This might make you go bonkers. Well, not anymore. With the help of Steel and Stud, you will get all these details arranged in one place. Isn’t that convenient, for we can help you from budgeting to laying down the foundation?

Choosing the Right Location

You can always consider the importance of choosing the perfect location for your metal building. But why? Your metal building is your precious possession, so you must ensure it only gets the best care. While building the best metal building, you must keep an eye out where you will lay the foundation.

The location you choose for building your metal building will significantly impact its functionality and aesthetics. While checking for the locations, you must also keep an eye on the local regulations and whether or not you will need to pay any additional taxes.

Designing the Layout

Layout design is an important aspect of putting forth your metal building. While you may have an idea of what you’re looking for, it can be quite tough for laymen to decide what type of layout they’re looking for. Well, in that case, nothing would suit you more than taking the help of professionals like “Steel and Stud”.

While designing the layout, as professionals, we will help you understand how much space you will need for the entire building. Apart from that, we will carefully lay out the design considering storage requirements, functionality, and how you plan to use the space in the future. With our help, not only can you maximize the space for efficiency but also the functionality.

Choosing the Right Material for Your Metal Building

Coming up with the metal building, the basic and most common material to use is metal. Different types of metal are used, sometimes for different purposes. Steel is considered sturdier, more durable, and a better tolerant material compared to iron. Red iron is even more preferred for large-scale buildings.

Iron sheets may be preferred for the roofing while the interior may use wood designs. All this depends on the precise function of the material and the particular features the materials are being used for. To decide on the best material to use, we offer consultation and send our professionals to work it out with you.

Obtaining Necessary Permits

Let’s admit it, without considering the building codes and local regulations, building your metal building is no less than a hassle. As the owner, you are responsible for taking the permit even before starting the construction procedure.

Your local authorities can guide you best in obtaining the permits. They can help you fulfill the requirements such as zoning regulations or environmental permits. At “Steel and Stud”, we encourage contacting the authorities early to receive the permits to avoid complications and delays. If you are in a dilemma as to who to approach and how our experts will walk you through the entire process.

Site Preparation

Site preparation is your go-to after you’ve fulfilled the above requirements. One primary reason why it is essential to prepare the site is to pay down the foundation carefully to ensure longevity. If the respective property has the smallest element that can cause a delay to your construction, you need to clear it.

Ground clearance is one of the most important aspects of site preparation. Since you’re indulging in building a metal building, you will need a lot of water and electricity. So, you must ensure that these facilities are easily available. If you’re new to the process, it can be overwhelming. So, you can take the help of our professional team to understand how to prepare the site for metal buildings.

Features of A Metal Building

Whatever the project you are coming up with, Steel and Stud is the most ideal partner as we offer the following features to you;

One Source

Steel and Stud is your one-stop shop for everything you need to start constructing your metal building. This will save time that would otherwise be lost in looking for suppliers and also in choosing which material is the best compatible with the others. Well, saving time saves the most precious resource!

Cost friendly

Among the most essential considerations for project owners is the price that the project is going to cost them. Steel and Stud is an undisputed partner in offering price-friendly goods and services to actualize your metal building idea. We offer on-site assistance, and you can consult our various professionals. We walk with you step by step into finalizing your dream construction plan and eliminate construction errors that may lead to unplanned costs.

Flexibility

Metal buildings are among the most accessible type of buildings to change their size by expanding or making them smaller. You acquire the additional size, remove the end wall, install a new framework, and match the walls and the roofs, and kudos! It is done.

Aesthetic Appearance

Steel and Stud have perfected the art of giving our customers attractive carports and metal building kits. Besides, we customize the structures as you would like them to be. We also add bricks, wood, stone, or glass, to different parts to ensure the beauty and design desired by our customers.

Maintenance

Metal buildings offer a significant advantage as they eliminate many maintenance problems. With metal buildings, you are assured of little structural deterioration caused by rot, cracking, and destruction by rodents and mites. This means that you end up with a reliable structure and you save a lot in the long run.

Lower Energy Bills

Insulation is one of the features that we put a lot of emphasis on. A building that has good insulation reduces the cost of heating and cooling.

Fast building for fast occupancy

Metal building projects from Steel and Stud have a completion schedule of two-thirds less than the total time required to construct other buildings. This results from quality factory-produced wall panels, roof, and doors among other components parts. We ensure that we pre-fix the components and the specific parts to ensure that no errors occur.

Customizing Your Kit

Although our metal carports have a standard look, our customers are given the privilege to decide on the design that they want for their metal buildings. Designs can vary in terms of size, shape, color combinations, material type, type of doors and windows, and landscaping. We offer an opportunity to negotiate and discuss with our client 3D designs availed on how the metal building will look in the end.

Installing a Metal Building

- The assembly of a metal building is a process that begins even before the metal building itself is brought on site. The assemble begins by determining the exact location where the building is to be erected.

- Measurements of the area to be covered are taken precisely.

- The area is cleared, with trees, bushes, and other obstacles removed.

- The ground is dug and leveled to prepare for the installation of the foundation.

- Concrete is the most preferred type of foundation for metal building installation, as it is strong and acts as the floor of the metal building once complete. Piers are fundamental in holding the frames firm,

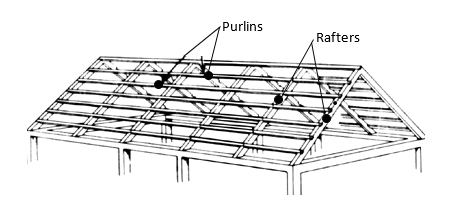

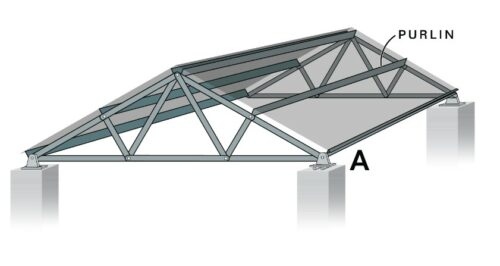

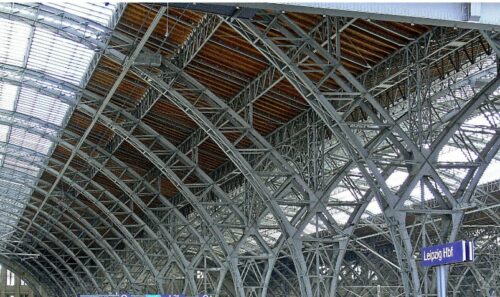

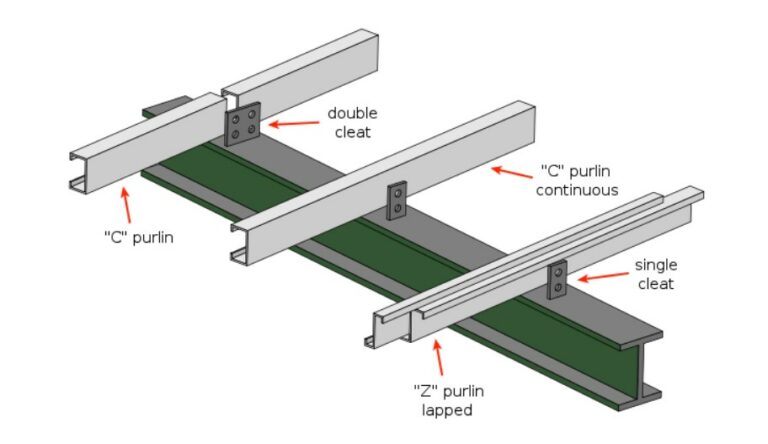

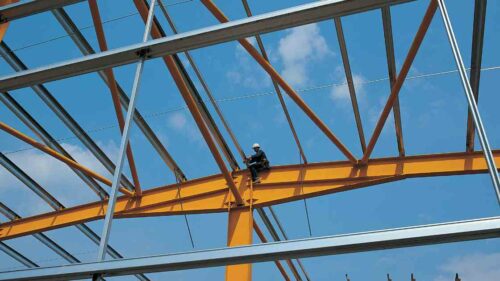

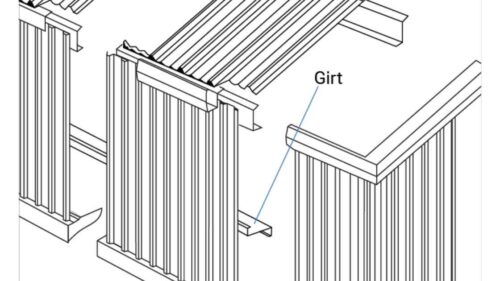

- Installation of the frames and what would be described as the skeleton of the building is done,

- Wall panels, roofing, gutters, and flooring are done,

- Electricity, water, and insulation of the building are fixed

Unloading Your Metal Building Kit

Unloading your building kit is a technical activity that, if done wrong, could cost you a lot of money. Below are some steps to follow;

- One of the most fundamental things to consider is safety for those unloading the steel building kit and those around. You should also ensure that you use clear-headed equipment while operating.

- Ensure the unloading and staging area is level with stone, concrete, and paving. This helps to avoid damage and injuries emanating from accidents.

- Stage your metal building kit according to the installation order

- Use quality chokers and harnesses that don’t have frays to avoid dropping the material.

- Use spreader bars when unloading material and equipment that is wider than 30’.

Storing Your Kits

Building Kits should be stored in dry places. Some metals may begin to rust if exposed to water. The building kits should also be stored in places where it cannot harm people or children. Store the steel building kit in an area that does not obstruct movement and the daily activities.

Types of Metal Buildings

There are many types of steel building kits to get from Steel and Stud. The metal building kits include;

Metal Carports and Metal Garage: Store your valuable items like your car, and farm equipment, among others, in a dry and secure place. Shelter them within your compound from snow, fire, sun, and storms.

Metal Barn: Construct attractive houses for your animals and keep them safe under the metal barns or shed. Barns can also be converted into beautiful homes known as barndominiums. Check our earlier articles on beautiful barndominium ideas.

Metal RV covers – These protect and shield your Recreational Vehicle while not in movement.

Metal workshops: You can assemble a small building serving the purpose of a workshop within your property.

Lean-to-metal building – These are steel building kits attached to the main house on one side, thus the lean-to.

Cold-formed steel building kits – these use a particular type of steel. Cold-formed steel building kits are easy to install and do not require welding, as other steel buildings would.

Customization Options for Metal Building Kits

Steel and Stud understand that every customer is different from the other and that the interests of one differ from the other. With this, we ensure that we offer our customers all the freedom to customize what type of building they would want. This is achieved through the customization options that we offer.

- The customer can purchase from a wide range of metal building kit designs by our sales agents.

- Also, our customers can come to our store and present the type of metal building kit design they want for their structure to our technical people. Customers can make up the designs themselves or come with designs from other architects.

- A customer can create a building design together with our architects from scratch.

Conclusion

Instead of paying a contractor extra to set up your Metal shed, garage, carport, or building, you can do it yourself by using a metal building kit. Besides, you are a do-it-yourselfer person anyway, and everyone knows it! “Steel and Stud” offer the best metal building kits throughout the United States.

Frequently Asked Questions

DIY steel building kits are an affordable solution for building a metal building. However, you must not indulge in DIY if you’re doing it for the first time to avoid safety hazards.

Since building metal buildings is not easy, you need to look out for potential dangers like height, operating tools, and more. Well, the best thing to do in such a situation is to wear all the protective gear.

Hiring a professional contractor for building the metal building can help you save money and also avoid any safety concerns especially in the long run.

You should consider taking up the metal building project on your own only if you’re experienced enough in handling construction projects.

Building a metal building requires precision, patience, and necessary tools. Therefore, you will need equipment like ladders, wrenches, screwdrivers and more.