What Is A Purlin? Types, Sizes, Designs, Accessories & Cost

- Kunal Singh

Table of Contents

Introduction

In structural engineering, construction, and architecture, a purling – also defined historically as purline, per line, purloined, or purling – is a horizontal bar or beam whose purpose is the structural support of the buildings. The purlins are commonly constructed in support of the roof system.

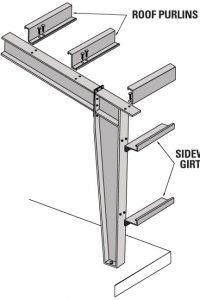

They are supported either by rafters or the walls of the building. Purlins are mostly used in metal buildings, although they sometimes replace rafters close to each other in wood frame structures.

Purlins are commonly used in pre-engineered metal constructions. They pass loads of the roof system including the roof sheeting to the major elements of the steel building construction that support the roof. The arrangement and form of the purlins are in such a design that depends on the instance of roof loads besides limiting the sheeting lengths used.

Conclusively, for the construction of building roofs, local building codes ought to be understood fully and implemented in the concrete roof structure design.

Steel Building Vs. Wood Buildings Roofing

Wood Building Roofing

Wooden roofing commonly uses trusses as principal rafters. The closely spaced rafters are the skeletons of the roof deck, and they support the walls of the building by carrying the weight of the frame thus lightweight timber frame construction.

Trusses are paramount in the wood building roof since they prevent the building from flexing or bending, more so in buildings with more than two stories.

Wood building roof trusses are installed manually by use of a crane or forklift, where the choice of either depends on the height of the building and the size of the truss. Truss connections are made with metal plates that fasten and ensure strong connections are achieved.

The roofing of a wooden building is faced with the dangers of decay, fire, and termite infestation. Wood can combust and, thus, burn in case of a fire outbreak. Termites and insects can pore through the wood and “eat” it up, destroying the roofing.

Metal Buildings Roofing

From garages to warehouses to workshops, steel structure roofing is preferred for steel buildings for several reasons. Steel is not only durable and affordable but also provides several functions that enhance comfort.

There are three general types of steel structure roofs. The truss structure, beam structure, and grid structure.

The Steel Beam Structure

This is suitable for buildings that have small spans. The I-beams, H-beams, and channel steel are all hot-rolled hot-rolled sections used in the steel structure roof.

The Truss Structures

The truss structures refer to the truss beam. This latticed beam structure is often used in large-span buildings such as stadiums, factories, bridges, and exhibition halls, among other large public buildings. Its web comprises small cross-section rods and is referred to as an open web or lattice beam.

Grind Structure

This is a spatial structure that is formed by connecting several rods through nodes in a particular grid form.

The roofing style has the advantage of small space stress, high rigidity, good seismic performance, and lightweight.

It is ideal for use in roofing buildings such as stadiums, exhibition halls, hangars, theatres, and two-way large column spacing workshops, among others.

However, this type of roofing installation is very complex and requires a skilled person.

Types of Purlins

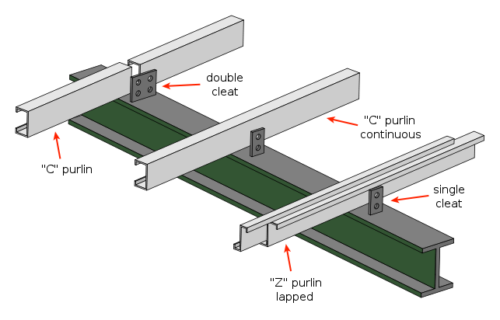

Purlins are in two types. C purlins and Z purlins.

C Purlins

C purlins are also referred to as Cee purlins. They are in C shapes or U shapes, thus the name C purlins.

The purlins give structural support for beams used for flooring and walls. Besides roofing, C purlins are ideal for floor joists and structural support in walls.

Advantages of C purlins

- Ability to span length

- Assured straightness

- Durable

- No side drilling required

- No cutting required

Z Purlins

Z purlins are also known as Zee Purlins. A purlinis a horizontal beam placed and form the roof and wall joists of a building’s shell structure.

Just like C purlins, Z purlins derive the name from the shape of the letter Z.

The shape of the purlins helps in overlapping the joints that, make them sturdier and stronger compared to the C purlins. Because of their strength, Z purlins are used for large structures.

Advantages of Z purlins

- Superior strength

- Z purlins can be overlapped

- Significantly saves material by reducing the height of the purlins

Red Oxide vs Galvanized Metal Purlins

The metal purlins are usually available in the market in two variations: red oxide (also referred to as red iron) and galvanized. Red oxide purlins with red iron buildings can disguise the appearance of rust on the structure. These two types of finishes are meant to protect the steel structure. If the steel structure is left bare for a few days, it may catch rust from exposure to various elements.

In terms of red oxide, it contains a spray-painted primer with a red finish. On the other hand, the galvanized metal purlins undergo a strict zinc-alloy plating process for a better impact. On being plated, it becomes resistant to corrosion. Therefore, the galvanized metal purlins can avoid damage even in the harshest weather conditions.

Even when the steel structure is deployed near a chemical plant or salt water, it will not cause damage. Rusting is common in these areas around unfinished steel. However, applying a coat of galvanized steel can help to avoid these.

Galvanized steel purlins for the roof will not be prone to oxidizing and will always be at risk of getting white rust. This white rust is unattractive and sometimes forms when exposed to moisture. However, red oxidized metal purlins are also prone to developing rust on the surface if it is exposed to humidity for way too long on the different types of metal roof. However, the only benefit, in this case, is that the red painting will easily disguise the red color of the rust.

While these two have major functional differences, the structure has no significant differences. If you want these, you can get it from “Steel and Stud”.

Spacing for Purlins

Spacing for metal purlins is important to consider before erecting the system. The general rule is that the larger and heavier a metal roofing structure is, the more space is needed between the purlins and the principal rafters.

The common standard distance in most buildings ranges from 12″ up to 24″. However, some buildings are an exception; thus, this can be customized depending on the customer’s needs.

Many building codes and manufacturers of metal roof purlins recommend;

That the purlins should not be more than 30 inches on center when they are being used to support steel framing and the secondary framing and 38 inches when only carrying sheathing.

When spacing metal roof purlins for long spans during light-frame constructions, contractors and engineers should offer good judgment.

The following tips can be considered;

That is, if the number of purlins in a span exceeds 5, then the center-to-center spacing should not be more than 30 inches. In such a case, you can use additional purlins instead.

That in case the roof span is more than 50 feet which is 15.24m, then the design of the purlins should come in pairs by incorporating a single higher purlin placed at the center supporting two lower spans placed at spaces of 30 inches apart.

One end post be placed for every long span. The end post should be at least 200 feet, fitted to support the purlins with a bearing plate.

Size of Purlins

A purlin may be manufactured in varying sizes, also known as gauges. Both the C purlins and the Z purlins are available in three varying gauges.

There are; 12 gauge, 14 gauge, and 16 gauge. To determine the best gauge for your project, consult your service provider or engineer.

What are Girts and Purlins?

In a structural steel construction, purlins and girts are two complementary products that you cannot miss out. They are primarily used in the roof and walls of the building.

Steel building constructions made by Steel and Stud use the girts and purlins, which are cold formed members extruded using high-strength steel that maximizes weight besides maximizing capacity for each section.

Steel and Stud offer cut-to-length painting and punching services besides offering our clients with a complete solution for your construction, thus reducing costs.

What is a Purlin Roof?

A purlin roof is a roofing type that is designed to use purlins. Metal purlins support the roof’s deck weight. They create a horizontal frame designed to completely offer support for the roof decking no matter the type of material used for the roof.

A purlin roof is more rigid and sturdier. You can create a wider building since a purlin roof incorporates mid-span support.

A steel building’s purlin roof can be achieved through two types of metal purlins. The C purlin and the Z purlin.

What is a Purlin Span?

Purlin span is the distance between the centers of each purlin. Each type of span represents a complete purlin system. There are three types of purlin span systems. They are;

Single Purlin Span

This is a span that is supported by bolting the purlin web to a cleat.

Under such conditions, inward capacities are not affected by bridging, but the outward capacities vary depending on the available number of rows used for bridging.

Double Purlin Span

Double purlin spans support each other in equal spaces, one on each and another at the center. The double span may contain only one long and full-length purlin or two purlins that are lapped together at the central support points.

Continuous Purlin Span

A Structurally efficient continuous beam is made is achieved by a purlin supported at every endpoint of a series of immediate supports that are equally spaced. Metal purlins are supported over each support where the length of the lap is 15%.

For outward loads on the continuous spans, bridging is required at the end. For internal spans, one less row of bridging may be used.

Purlin Accessories

Purlin Laps

Purlin laps are recommended at a length of 15% of the span. Where there are unequal lengths of the span, especially created by reduced end spans, each purlin ought to have 7.5% of the adjacent span instead of 7.5% of the whole purlins span.

The lengths of the purlin laps that are less than 10% may not effectively provide structural continuity and may suffer from failures.

Purlin Cleats

There are single cleats and double cleats. Single cleats are used in many situations, including the Z shapes that are lapped onto each other.

Double cleats are used in instances of successive metal purlins – unlapped purlins – and are butted together. The double cleats could also be used in places with high reaction loads to reduce bolt stress.

Purlin Designs

Purlin sections assume the roof slope. The spacing of the purlin must be carefully calculated in that, it should follow the nodal pattern for truss support. There are two types of purlins, the Z shapes and the C purlins.

In terms of the arrangement, the design can be reached depending on the supply length of the sections, the loading and roof span, the need to avoid wasteful cuts, and the principal rafters arrangement.

Installing Purlins

Purlins are installed in a horizontal way below the metal roofing. They are installed above the roof rafters with a vapor barrier installed at the top.

These purlins are in the dimensions of 2 feet by 4 feet, and their installation is similar to that of the metal roofs.

They provide added support to the metal roof as well as providing a surface for nailing the drip edge and the end panels.

Importance of Roof Purlins

Purlins are very fundamental in the construction of metal roofing. They offer support to the metal sheeting above, as well as offer support to the walls.

Purlins are essential in ensuring that the metal building is sturdy and rigid, keeping it safe from crumbling or caving in from the roof.

Do's and Don'ts for Purlin Construction

Spacing

The spacing of purlins depends greatly on how apart the trusses are spaced for wind loads, dead load and gravity.

It is, therefore, important to determine the maximum spacing with the design of the truss. Maximum spacing in the post should not go beyond 24″ on the center.

If the span is wider, ensure that you factor in the effects of truss bracing, purling strength, diaphragm strength, and chord forces.

Overlapping ends

Overlapping of ends is stronger and preferred compared to butting. Do not butt longer spans; instead, overlap them for maximum and multiple supports.

Overlap ends at 12″ pass the truss. Do not connect purlin ends through “butt joints” using a thin gauge splice plate.

Purlin Placement

Purlins should be placed standing up. Do not lay purlins flat.

Cost of Metal Purlins

Prices of metal purlins vary depending on the size of the purlin, its thickness, and the job site.

For instance, heavy gauge purlins are more expensive than lighter gauge purlins. Deeper purlins are made of more steel than shallow purlins. A 10″ deep purlin is double the cost of a 4″ purlin.

Why Choose Steel and Stud for Purlins?

Steel and Stud is your best bet for quality purlins. We have been in the production market of purlins for a long time, which has made us become experts in the field.

We offer quality purlins derived from quality steel. Using advanced technology, we come up with precise measurements besides cutting the purlins with accuracy.

Once you begin the installation of your purlins, we offer you consultation services until your project is over.

We also offer various designs to use in your metal building, giving you a chance to try out the best cost effective and safe roofing styles.

FAQs Related to Purlins

Purlins are very lightweight, accurate, and simple. Compared to other building materials, purlins usually have a stable dimension, which is vital in adding structural integrity to the metal building. They can also expand and compress effectively in extreme temperatures, preventing significant property damage.

The metal roofing purlins are meant to enhance the structural integrity. These are mostly used around the roof. Moreover, the purlins are also used for tying the rafters together. This helps to stabilize the entire structure and provides a rigid frame to the framing structure. Purlins can offer an extra support layer when installed between individual framing bays.

The rafters are wood beams usually installed facing upwards from the ground. Usually, their point of junction is at the ridge beam, which features extra bracing to be attached to the rafters. On the other hand, the purlins stand in a perpendicular position to the rafters. They can be connected in regards to the presence of the rafter to provide structural strength to the particular metal building.

Purlins are horizontal structures on a metal roof. Their primary purpose is to protect the struts installed across the metal buildings. Therefore, these purlins provide immediate support to the roof. But, the struts transfer extra layers of load or support.

The Z purlins are considered to be the strongest purlins. This is mostly because they can easily withstand the weight of heavier structures. Z purlins usually feature bigger loading and roofing capacity, which further plays a vital role in providing support to structures across larger areas. As a result, the Z purlin may be used in industrial and agricultural structures.

Purlins need equal support from both ends to prevent significant damage. It is advisable to check the purlins for damage constantly. Once these are fixed, it is advisable to continually clean or galvanize the purlins to prevent the risk of rust.

Indoor Riding Arenas: Types, Features, Benefits, and Cost

Different Types of Metal Roofing for Commercial and Residential Buildings

What Is A Purlin? Types, Sizes, Designs, Accessories & Cost