What makes Metal Building Non Combustible Building- Its Construction components

- Kunal Singh

50% of industrial accidents are the result of a fire. Buying high-quality metal frame components or a pre-fabricated metal building kit from Steel and Stud can ensure fire resistance. Non- combustible metal structures usually contain components that show a high rating during the heat testing of ASTM (American Society for Testing and Materials).

Components that go into metal building construction make it non-combustible, meaning they will not add fuel to the fire, unlike wood. Metal, stone, glass, concrete, clay products, gypsum products, and asbestos products are building components known for being anti-fire or fireproof.

But, be it metal or otherwise, no building is fireproof.

However, extreme temperatures in the US can melt or warp the metal building and cause it to collapse.

Or, during an accidental fire caused, high temperature can corrode steel and deteriorate the mechanical properties of steel structural elements. An elevated temperature culminates in stiffness and a lowered yield strength. Local buckling, deflections, and twisting of the building components further damage the building.

Table of Contents

Metal Components In Metal Building That Can Make it Non Combustible

The different components of a metal building play an important role in making it non-combustible. It’s the same material that also provides a strong structural framework. Steel is one of the most popular components of metal components. Being fire-resistant, it prevents the metal buildings from being on fire.

Component Used in Metal Building Structure

Structural integrity is one of the major requirements of metal buildings construction. There are different components for metal buildings that help in maintaining strength and providing structural integrity. Some of the prominent options that offer structural integrity to your metal buildings include:

- Columns: Columns are long and bear all the load. Since it is vertical, it helps to transfer the entire pressure or weight for the same to be transferred to the foundation.

- Beams: While columns are vertical, beams are horizontal. As a result, the beams provide extra support to windows and doors. This plays a vital role in providing equal balance to the property.

- Truss: Columns and beams offer weight distribution only across certain areas. However, you must know that the truss distributes weight across all sides equally, thereby maintaining the strength of the entire property. Truss has a unique structure of a triangle which helps distribute the weight equally.

It is extremely important to use high-quality materials to construct metal building components. We help you get the maximum advantage at Steel and Stud by constructing all components using high-quality materials. If you want to increase the aesthetic appeal, opt for the metal building colors.

Exterior Cladding

The exterior cladding contributes to making the entire metal building fire-resistant. Since the panels are an essential part of the cladding, it is crucial to choose the right materials. You can either opt for regular panels or masonry. Both can help prevent fire by acting like a protective barrier. Furthermore, it also prevents the metal building interior from being damaged as it does not allow the flames to spread.

Roofing Systems

Metal building roofs can also protect your structure from fire if you use the right materials. Some of the prominent metal building roofing materials can easily withstand higher temperatures. As a result, there is a lesser risk of fire damage. We understand all the risks involved at Steel and Stud, so we use only the best and strongest materials to build the roofing system. Therefore, we mitigate the risk of the roof collapsing in case of any fire breakout.

Fire-Resistant Insulation

Insulating your metal buildings can only be possible using non-combustible materials like fiberglass or wood. You can build metal building exteriors using these non-combustible materials to improve aesthetic appeal. You can install these on your roof to provide extra protection during fire breakouts. One of the best benefits is that they prevent the fire from spreading and help maintain the overall integrity of the metal building. Furthermore, metal is not prone to fire which also prevents the property from getting rot.

Fire Protection Systems

A fire protection system is no longer a luxury but an essential requirement today. These play an important role in adding an extra layer of safety to the metal buildings. You can include various fire protection systems such as fire alarms, sprinklers, smoke detectors, or fire suspension systems. You must consider adding these as early as possible to prevent any risk of fire damage. After all, the earlier it is detected, the earlier you can mitigate the risks.

Fire Damage Can be Lethal At Times

Fire damage can be of three types — physical, structural, and cultural.

Physical damage would make the quarters unsuitable for living until repairs are made.

Structural damage occurs when the building will be collapsed or is on the verge of falling over.

When fire destroys personal property, and this loss can be recovered through insurance claims, it comes under cultural damage.

Roofs are often one of the first things to collapse when a building burns, and they wouldn’t be able to support the structure for much longer.

Floors gradually weaken from smoke and heat, which could ultimately make the foundation unstable.

If the building lacks fire-resistant materials or firewalls, there is a high risk of casualties and total destruction. With noncombustible material, no more burning and collapsing of metal buildings- this is what we strive for as your building contractors.

Is a metal building considered non combustible?

While there are fire-resistant materials, no building, not even a complete metal construction, can be considered fire-resistant. The words fireproof and fire resistance can be used interchangeably. Fire-resistant or flame-resistant materials can withstand heat and, at the same time, prevent the spread of fire. Once the source of fire is removed, flame-resistant materials get self-extinguished.

Fire protection systems include equipment such as smoke detectors, sprinklers, and fire suppression systems that work to protect a building and its occupants against fire.

What is a Non-Combustible Building? Construction class

Buildings can be categorized into five types — fire-resistive, noncombustible, ordinary, heavy timber, and wood-framed.

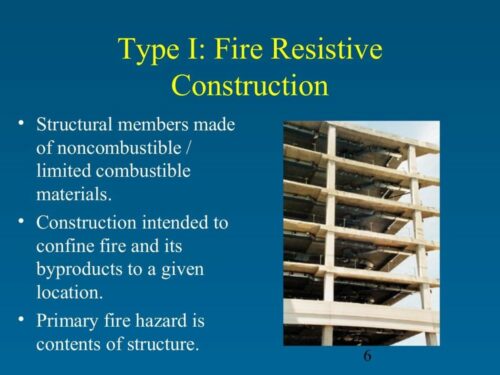

Type 1 - Fire Resistive Construction

Type I or fire-resistive construction include high-rise building composed of non-combustible materials such as reinforced concrete or protected steel and poured concrete.

Type I structures are more than 75 feet tall. Fire-resistive construction offers a fire-resistance rating that guarantees fire protection performance endurance against fire and its effects. The model building codes determine specific ratings for roof and floor assemblies and exterior or interior bearing support walls for specific types of construction.

Different designs provide different fire-resistance ratings to meet minimum performance. These are designed to withstand fire for a considerable time and prevent it from spreading. Type I fire-resistive non-combustible components are generally found in exterior walls, structural frames, roof protection, and floor/ceiling assembly of high-rise buildings.

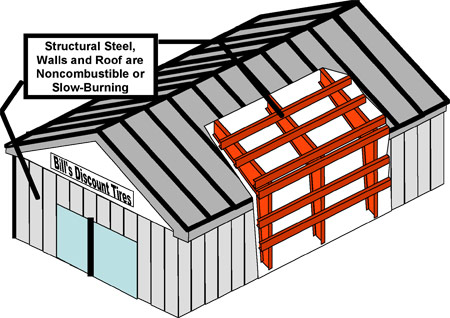

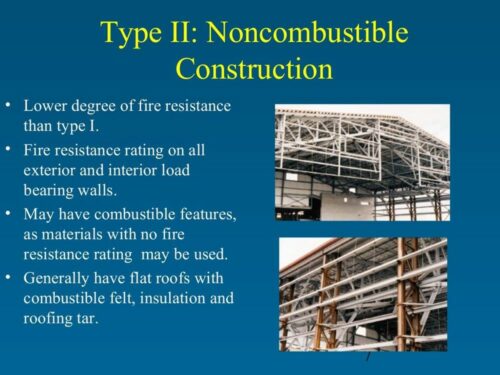

Type 2 - Non-Combustible Metal Building Construction For Fire resistance

Type 1 and ii have the same requirements except for some differences. This type of construction doesn’t offer any fire-resistance rating for the exposed structural elements. If it provides a rating, then it’s lesser than that required by Type 1.

In this construction, the structural components are made of steel welded or bolted together. These are less fire-resistant, easily susceptible to distortion, expansion, or relaxation of the steel parts during a fire event, and can result in an early collapse of the structure. These cannot withstand high temperatures or keep the fire spread in check. Type 2 protected non-combustible construction is usually found in newer school buildings.

Type 2 unprotected non-combustible construction is employed in remodeled commercial structures. Metal or masonry walls and exposed metal floor and roof systems are characteristic of this type of construction.

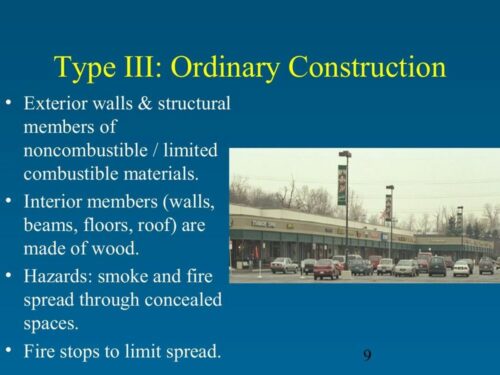

Type 3 - Ordinary Construction

Ordinary construction is characterized by combustible roofs, floors, interior walls, and noncombustible masonry exterior walls, i.e., masonry, concrete, or brick. Type iii construction can be categorized into protected combustible and unprotected combustible subtypes.

Protected combustible buildings comprise brick or block walls and a wooden floor assembly or roof, which is 1-hour fire protected. Unprotected combustible type iii constructions include walls, floors, and roof that is not protected against fire. In these types of construction, masonry walls have a 2-hour fire rating, and interior partitions, floors, and roofs are made of wood.

They often feature a wood roof support structure, but it’s not uncommon to find steel bar joists. Composition board and plywood are notably used for floor and roof decking.

Connected attics and common walls between such construction types can share wall sockets for roof rafters and floor joists. These structures don’t usually exceed six stories and are often only two or three stories in height. Older buildings of this type can have conventionally framed roofs, whereas newer structures often feature lightweight roof systems.

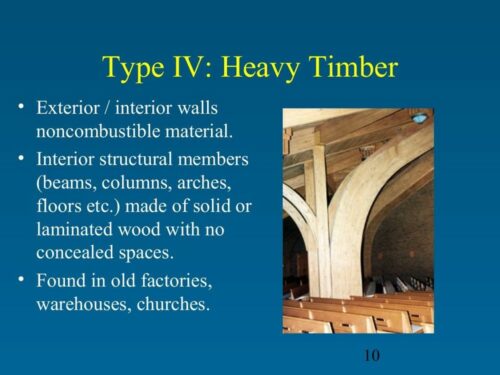

Type 4- Heavy Timber Construction

Also known by the names of mill construction and post and beam construction, type iv construction uses rustic, large, and heavy sawn timbers or laminated wood, joined with modern metal joinery or traditional mortise and tenon joinery. Heavy timber is mainly used for main beams and posts.

Heavy timber construction type provides through both interior structural elements and exterior walls an aesthetically pleasing structure that can be next to impossible to achieve with steel.

However, it is likely to bend, crack, and decay if not properly taken care of. It demands a high level of maintenance as well. Heavy timber is also easily susceptible to fire. It would require copious amounts of water to extinguish a fire event.

Type 5 - Wood Frame Construction

These types of building construction require combustible materials such as wooden members. They can be classified into protected wood-framed construction and unprotected wood-framed construction.

There is no exposed wood in the protected wood frame variant, but in unprotected wood frame buildings, such as single-family homes or garages, exposed wood is common as they offer no fire resistance.

The primary structural frame is constituted by basic building elements such as bearing walls, floors, roofs, and non-bearing walls. Thus, these are the only structures that allow combustible exterior walls. Wood, when compared to concrete, glass, or steel, has a low thermal conductivity, thus retaining heat and making wooden homes energy-efficient.

Issues of fire resistance and wind resistance, low thermal mass, durability, shrinkage, and sound insulation are encountered with wood frame construction. Also, lightweight construction of this type can collapse within moments after a fire starts.

So, Is wood stronger than concrete?

Wood is a combustible material that is less dense when compared to concrete and, therefore, less durable.

Fire-Resistant Construction Materials

Different construction materials are fire-resistant in nature. Therefore, if you want to protect the integrity and ensure the longevity of the metal building, you must choose the construction materials properly. Below are some of the prominent fire-resistant construction materials:

- Steel: As discussed above, steel is one of the major components of the metal building. As it is non-combustible, there is no risk of the fire spreading. Steel often forms the base structure of a metal building.

- Concrete: Concrete is one of the primary materials used for constructing floors and metal building foundations. Concrete is very durable and offers a solid structure for the entire building. Apart from that, concrete also does not catch fire easily, which makes it a reliable fire-resistant construction material.

- Glass: If you want to make your doors and windows fire-resistant, it is advisable to opt for fire-rated glass. If you need clarification about the same, you can consult our Steel and Stud professionals regarding installing fire-rated glass.

- Masonry: Bricks and blocks can form an essential part of the exterior of your metal building. You can opt for these over the metal buildings to prevent fire from spreading.

- Gypsum: You can opt for gypsum products such as panels and boards, as these are fire-resistant. Installing these across the ceilings and interior walls is advisable to prevent fire risk.

International Building Code and Fire Resistance rating

The metal building kit for related construction and structural fire resistance are governed by the International Building Code (IBC). This resource basically determines the fire-resistance rating. The ratings are measured based on the time a structural component can be exposed to fire before it falls over. So, for example, if a beam is assigned a fire rating of 2 hours, it can be exposed to accidental fire for at least two hours. If a component has a rating of 0 hours, the material will fail in less than an hour.

The structural members typically used for type I construction normally receive three- to four-hour protection from fire.

Wood and other structural wood supports associated with the type iv construction and type 5 are assigned a resistance rating that varies based on thickness.

According to the National Design Specification for Wood Construction, in line with American Wood Council, a nominal char rate of 1.5 inches of wood thickness per fire resistance is acceptable per hour.

Advantages of Non-combustible Building

Structural materials of noncombustible buildings are fireproof, meaning they have fire-resistant properties, do not easily burn, and can protect the construction for up to four hours. These do not easily collapse either. Besides, these are economical to build and easy to erect.

Day-to-day life Disadvantages of Non-combustible Building

Noncombustible construction largely comprises steel which can lose its strength in high temperatures. The structural integrity of these constructions can be compromised after a fire. The materials that go into making both old and new buildings are slow-burning in nature. Eventually, if the fire suppression systems fail, they will act as fuel to the fire.

Are You Looking for Good Quality Materials?

Apart from giving your building an aesthetic value and durability, using good building materials in construction is of paramount importance. It determines your structure’s quality and ensures long and healthy life. Steel and Stud can help you procure high-grade materials for your construction work. We have been serving clients from different sectors for several years now, and the experience we have earned has helped us carve a niche in the construction industry.

Besides providing metal building kits, we also help set up ventilation systems and offer building construction materials with great fire-resistive properties. We extend our services towards residential, commercial, and industrial ends. Our team of experts can provide professional guidance to help you make considerable progress in your journey. Tell us what you want and how you want it — ensuring client satisfaction at all costs is our core motive, and we strive to fulfil it.

FAQ's

According to the International Building Code, steel constructions are non-combustible. Since steel forms an integral part of metal buildings, a metal building, unlike wood-framed buildings, is thus noncombustible.

Newer buildings with reinforced masonry walls or tilt slab walls and a metal roof are considered non-combustible.

Masonry non-combustible is a Class 4 construction type where the exterior walls of the building are built using masonry elements, and floors and roofs are made of metal or other non-combustible materials.

Non-combustible walls are made using non-combustible materials such as steel, ceramics, or specific insulating materials like mineral wool insulation or fibreglass. Gypsum wallboard is considered non-combustible even though it has a thick combustible paper backing.

Indoor Riding Arenas: Types, Features, Benefits, and Cost

Different Types of Metal Roofing for Commercial and Residential Buildings

What Is A Purlin? Types, Sizes, Designs, Accessories & Cost